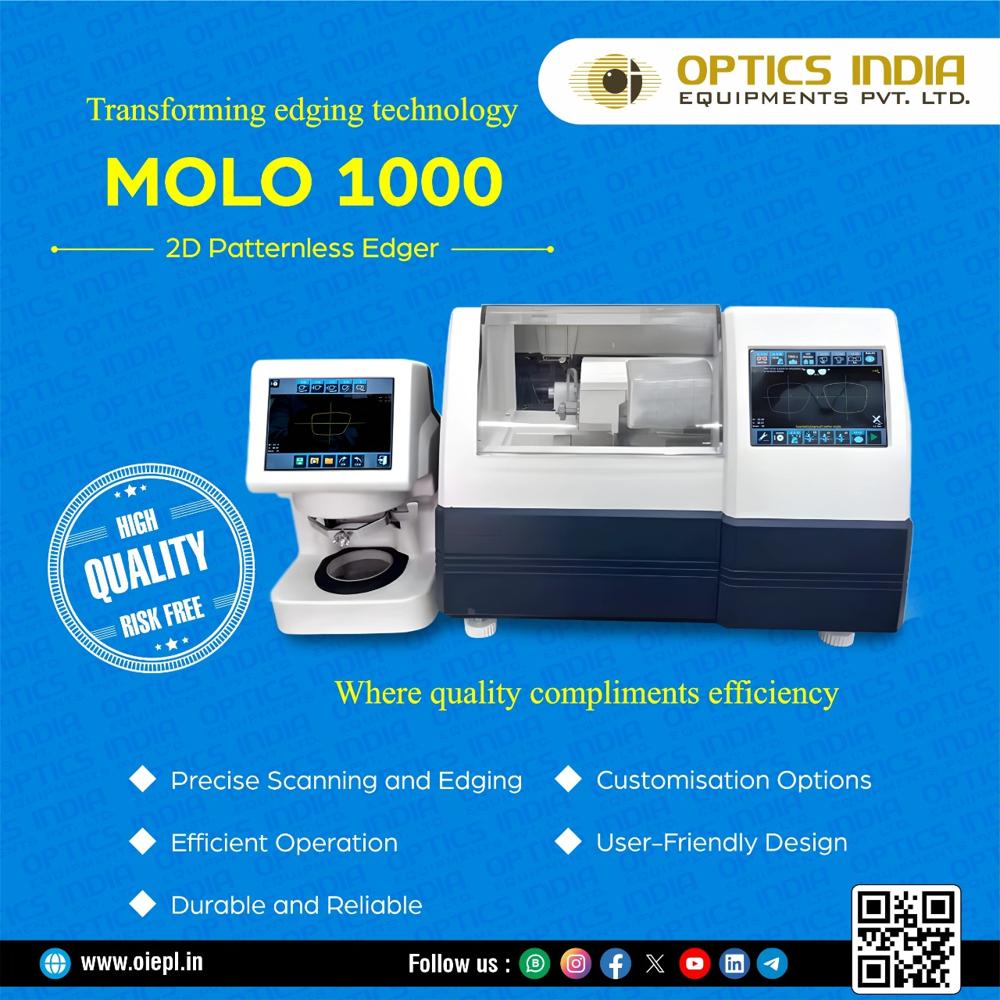

MOLO 1000 - 2D Patternless Auto Lens Edger

MOLO 1000 - 2D Patternless Auto Lens Edger Specification

- Objective

- Precise lens cutting and edging for optical labs

- Lens

- CR, Glass, Polycarbonate, Trivex compatible

- Theory

- 2D Patternless Edging

- Color

- Grey and Blue

- Measurement

- Automatic Lens Measurement

- Accuracy

- 0.05 mm mm

- Product Type

- Automatic Lens Edger

- Material

- Metal & ABS Plastic

- Size

- Standard desktop size (approx. 530 x 520 x 350 mm)

- Weight

- Approx. 38 kg Kilograms (kg)

- Length

- 530 mm Millimeter (mm)

- Function

- Automatic patternless lens edging, beveling, grooving, and safety beveling

- Resolution

- High precision with LCD display interface

- Cooling System

- Integrated Water Pump

- Bevel Type

- Flat, Mini Bevel, V-Bevel, Groove, Safety Bevel

- Display

- LCD Touch Screen

- Safety Features

- Overload Protector, Emergency Stop Button

- Processing Speed

- Fast Automatic Cycle (average 80 sec/lens)

- Applicable Material

- Supports various lens materials

- Data Input

- Manual and Automatic (Traced shape input)

- Power Supply

- AC 220V / 50Hz

- Clamp

- Automatic lens clamp

- Edging Mode

- Multiple selectable edging modes

- Operation Mode

- Touch Panel and Keypad

- Noise Level

- Low operating noise

About MOLO 1000 - 2D Patternless Auto Lens Edger

- High-Precision Edging: The MOLO -1000 lens edger features a 2D patternless design, ensuring precise and accurate edging for ophthalmic lenses. This advanced technology allows for efficient processing of various lens shapes and sizes, meeting the needs of optometrists and eye care professionals.

- Durable Construction: The edger boasts a sturdy design with a weight of 50kg, ensuring stability and longevity. Its compact dimensions of 705mm x 470mm x 450mm make it ideal for use in busy optometry clinics.

- Customization Options: The MOLO -1000 lens edger offers customization support through OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services, allowing users to tailor the product to their specific needs.

- User-Friendly Interface: The edger features an 8-inch LCD touchscreen with a resolution of 1024x768, providing an intuitive and user-friendly interface for easy operation.

- Reliability and Support: The MOLO -1000 lens edger comes with a 1-year warranty and is certified by CE and ISO, ensuring reliability and meeting international standards.

Precision and Versatility for Modern Optical Labs

The MOLO 1000 2D Patternless Auto Lens Edger embodies advanced technology, supporting various lens materials and edging styles. Its high precision, fast processing speed, and LCD touch screen make it suitable for a broad spectrum of optical lens applications. With multiple edging modes and safety features like overload protection and emergency stop, the device enhances workflow efficiency and reliability in busy lab environments.

User-Friendly Operation and Fast Processing

With both touch panel and keypad controls, the MOLO 1000 is designed for intuitive operation. Operators can input shape data manually or automatically, benefiting from an average 80-second cycle per lens. The integrated water pump and low-noise design further ensure a smooth, uninterrupted working experience, while automated lens measurement and clamping reduce handling errors.

FAQ's of MOLO 1000 - 2D Patternless Auto Lens Edger :

Q: How does the MOLO 1000 improve optical lens edging processes?

A: The MOLO 1000 automates patternless lens edging, supporting multiple materials and offering high-precision cuts. It speeds up processing with an average cycle of 80 seconds per lens and minimizes errors through features such as automatic measurement and lens clamping.Q: What types of lenses can the MOLO 1000 process?

A: This device can handle a wide range of lens materials, including CR, Glass, Polycarbonate, and Trivex, making it suitable for most modern optical lab requirements.Q: When should I use the different edging modes available on this machine?

A: The MOLO 1000 offers multiple selectable edging modes-such as Flat, Mini Bevel, V-Bevel, Groove, and Safety Bevel-to match specific frame and prescription requirements. Choose the appropriate mode based on the desired fit and visual outcome for each job.Q: Where is the MOLO 1000 typically installed?

A: It is designed for standard desktop use in optical laboratories due to its compact size (approximately 530 x 520 x 350 mm) and manageable weight (about 38 kg). Placement near power and water sources is recommended for optimal operation.Q: What is the process for inputting lens data into the MOLO 1000?

A: Users can input lens shape data both manually and automatically using the traced shape input function, which is accessible via the LCD touch screen interface or keypad controls. This flexibility streamlines the process for both routine and customized lens production.Q: How does the integrated cooling system benefit the usage of the MOLO 1000?

A: The built-in water pump cooling system ensures optimal operation by maintaining temperature stability during high-speed edging cycles, thus protecting lenses and machine components alike.Q: What safety features are included with the MOLO 1000?

A: Safety is enhanced with an overload protector and an emergency stop button, allowing operators to halt processes instantly if necessary and providing greater peace of mind during continuous operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Patternless Edger Category

Patternless Edger Briot Evolution

Price 2500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 45 Grams (g)

Color : White

Product Type : Patternless Edger Briot Evolution

VISIONIX Briot Couture Patternless Edger

Price 4750000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 100 Kilograms (kg)

Color : White

Product Type : VISIONIX Briot Couture Patternless Edger

Accuracy : +0.05 mm

Optical Lens Patternless Edger

Price 1500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 65.3 Kilograms (kg)

Color : White

Product Type : Optical Lens Patternless Edger

Accuracy : +0.05 mm

i-Optik Patternless Edger

Price 750000.0 INR / Unit

Minimum Order Quantity : 10 Units

Weight : 75 Kilograms (kg)

Color : White

Product Type : iOptik Patternless Edger

Accuracy : +0.05 mm

Send Inquiry

Send Inquiry